sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

KURZ Stamping Technology (Hefei) Co., Ltd (KST) is a wholly-owned enterprise invested by Kurz Group of Germany in China. KST is mainly engaged in the development of hot stamping foil, hot stamping tools, hot stamping application machines and ancillary products, etc. The products are mainly used in the fields of packaging industry, automobiles and communication equipment. Industrial boiler is an important energy equipment on the production line, which is used to provide the required heat energy for coating, drying and other processes.

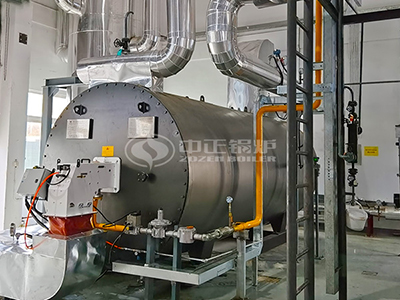

ZOZEN Boiler provides the gas-fired thermal oil heater for the multinational enterprise

According to the actual heat demand, ZOZEN Boiler recommends the horizontal gas-fired thermal oil heater. The boiler range covers 1.2 million to 12 million kcal, which can easily meet the daily demand of the enterprise. The intelligent control system of the boiler realizes the accurate temperature control and pressure control. The temperature difference is only about 1℃, which ensures safe and stable temperature supply and improves the quality of users' production process.

As the pressing and ironing production lines all adopt advanced systems from Germany, it is very difficult to connect the oil supply system of the thermal oil boiler. Through the cooperation of all parties, ZOZEN Boiler overcame technical barriers, successfully completed the docking of boiler oil supply system, and the gas-fired thermal oil heater system was successfully ignited and debugged, realizing long-term stable heat supply.

The thermal oil heater has wide capacity range, short installation period and low cost

The third-party energy efficiency test shows that the measured thermal efficiency of the boiler is as high as 95%. The nitrogen oxide emission is only 24 mg/Nm³, which meets the requirement of ultra-low nitrogen emission, energy saving and environmental protection.

I want to comment