sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

Spain’s food industry is one of the most dynamic and mature in Europe, encompassing key sectors such as olive oil extraction, winemaking, canned produce, and dairy processing. As energy prices across Europe fluctuate and environmental standards grow stricter, Spanish food enterprises are increasingly shifting away from fossil fuels toward renewable, locally sourced biomass.To support this transformation, ZOZEN Boiler provided the client with a 6 t/h Reciprocating Grate Biomass Steam Boiler solution specifically designed to meet the complex requirements of food-grade steam production and biomass fuel combustion.

The 6 t/h Reciprocating Grate Biomass Steam Boiler supplied by ZOZEN adopts a double-drum water-tube design, ensuring high heat transfer efficiency and excellent steam-water separation. This structure guarantees stable steam parameters and superior steam dryness—critical for maintaining hygienic standards and precise temperature control in food processing environments.

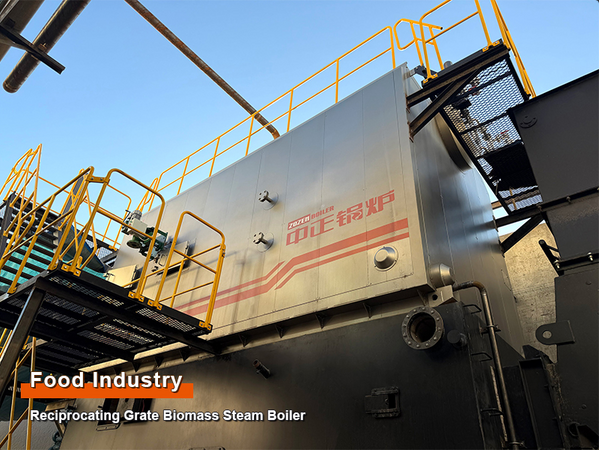

ZOZEN 6 t/h Reciprocating Grate Biomass Steam Boiler

At the heart of the system lies the reciprocating grate combustion system, designed to handle the variable particle size and moisture content of crushed olive pits and wood chips. The reciprocating motion continuously stirs and advances the fuel bed, preventing clumping and incomplete combustion. Combined with precisely segmented air distribution chambers, this design provides optimal airflow and combustion conditions at each stage—from fuel drying to complete burnout—maximizing thermal efficiency and minimizing unburned carbon loss.

In addition, the 6 t/h Reciprocating Grate Biomass Steam Boiler features a high-efficiency economizer at the tail section to recover residual heat from flue gas, further reducing overall fuel consumption. The system’s intelligent control platform enables automated feed adjustment, steam pressure regulation, and fault diagnosis, ensuring stable operation under fluctuating production loads typical in food manufacturing.

ZOZEN Boiler’s proven track record in the food and agricultural processing sectors has made it a trusted partner for enterprises seeking to balance energy efficiency with environmental compliance. The company’s biomass boiler solutions are backed by comprehensive experience in handling diverse bulk biomass fuels, including sawdust, rice husks, palm shells, and olive residues. Each project is supported by tailored air supply systems, optimized grate configurations, and precise fuel feeding mechanisms, ensuring combustion efficiency across various biomass types.

Moreover, ZOZEN’s robust delivery capability and global service network enable fast project execution and reliable after-sales support. From manufacturing to installation, all stages are governed by strict quality control standards. Through localized service points and remote monitoring platforms, ZOZEN ensures real-time operational assistance, improving equipment availability and minimizing downtime.

The deployment of the 6 t/h Reciprocating Grate Biomass Steam Boiler in Spain demonstrates ZOZEN Boiler’s ability to provide customized clean-energy solutions that align with European sustainability goals. By converting agricultural by-products into renewable heat sources, the project not only reduces fossil fuel dependence and CO₂ emissions but also strengthens circular economy practices in the food industry.

As a global industrial boiler manufacturer, ZOZEN Boiler continues to empower enterprises worldwide with high-efficiency, low-emission, and intelligent boiler systems. With continuous innovation and a focus on sustainability, ZOZEN is helping industries like Spain’s food processing sector transition toward greener, more cost-effective operations—embodying the company’s vision of “clean energy for a sustainable future.”

I want to comment