sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

When selecting a gas boiler, industrial users are often faced with a key question: should you choose a two-pass boiler or a three-pass boiler?

The difference in pass design directly affects heat transfer efficiency, system configuration, investment cost, and long-term operating performance. This article explains the core differences between two-pass and three-pass boilers and helps you determine which solution best fits your application.

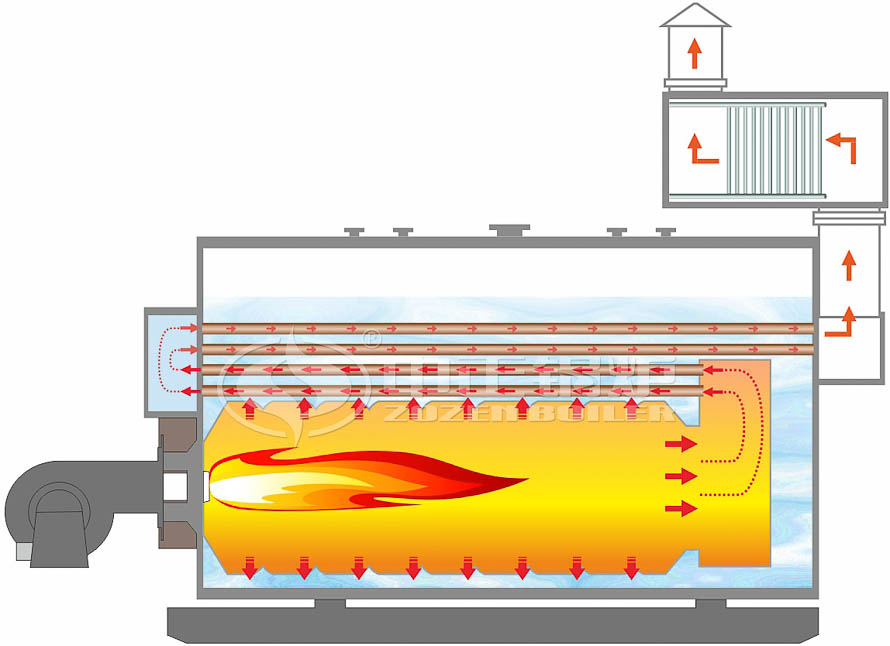

A two-pass boiler completes heat exchange through two internal flue gas passes and is often combined with economizers or condensers to enhance efficiency.

A three-pass boiler extends the internal heat-transfer process with an additional pass, allowing more heat to be absorbed directly within the boiler shell.

Schematic diagram of two-pass boiler

Schematic diagram of three-pass boiler

How to Choose Between Two-Pass and Three-Pass Boilers

Aspect | Two-Pass Boiler | Three-Pass Boiler |

Structure | Simpler design, compact | More complex, with extra heat exchange area |

Efficiency | Good, enhanced by external equipment | Higher efficiency, built-in heat exchange |

Cost | Lower material cost | Higher material cost |

Operating stability | Suitable for medium loads | Excellent under continuous high load |

In practice, both designs are mature and reliable. The selection should be based on operating conditions rather than pass number alone:

Choose a two-pass boiler if flexibility and lower initial boiler body cost are priorities, and external heat recovery systems are planned.

Choose a three-pass boiler if your plant requires long-term continuous operation, high thermal efficiency, and stable performance under heavy load.

Application Case: 15 TPH Three-Pass Boiler for a Paper Mill in Venezuela

In recent years, the global paper industry has continued to expand, driving strong demand for efficient, clean, and automated steam systems.ZOZEN Boiler successfully supplied a WNS series 15 ton three pass gas-fired steam boiler to a well-known paper manufacturer in Venezuela, marking another breakthrough in boiler applications for the paper industry.

ZOZEN’s solution delivered:

1.High efficiency and energy savings:The three-pass WNS boiler, combined with a corrugated furnace and threaded smoke tubes, significantly enhanced heat transfer, achieving thermal efficiency above 98%.

2.Low emissions:Equipped with an advanced low-NOx burner, NOx emissions were controlled below 30 mg/Nm³, meeting international environmental standards.

3.Intelligent operation:The fully automatic control system supports remote monitoring and automatic operation, simplifying boiler management and improving overall plant efficiency.

ZOZEN 15 ton WNS gas-fired steam boiler

This project demonstrates how a properly selected three-pass boiler can effectively support high-load industrial steam applications.

Reliable Gas Boiler Solutions from ZOZEN Boiler

ZOZEN Boiler provides both two-pass and three-pass gas-fired steam boilers that have been widely applied across paper, chemical, food, pharmaceutical, and textile industries. Each solution is engineered based on actual operating requirements to ensure high efficiency, environmental compliance, and long-term reliability.

If you are planning a new boiler project or upgrading an existing steam system, ZOZEN’s technical team can help you select the most suitable boiler configuration based on your specific production needs.

Contact us to receive a customized boiler selection proposal and technical consultation.

I want to comment