sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

Contact

Us:

Contact

Us:

Introduction

Boiler Parameters

Thermal capacity: 6-35 t/h

Working pressure: 1-2.5 MPa

Outlet temperature: 184-350℃

Available fuel: Biomass molding granules, wood chip, corn cob, saw dust, palm shells, rice husk, etc.

Available industries: Heating, chemical, food, tobacco, textile, print and dyeing, feed, medicine, building materials, wine, hospital

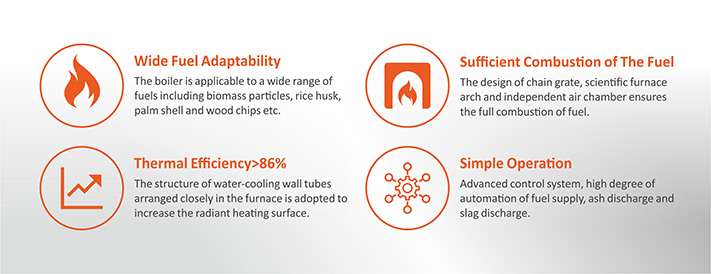

Boiler features

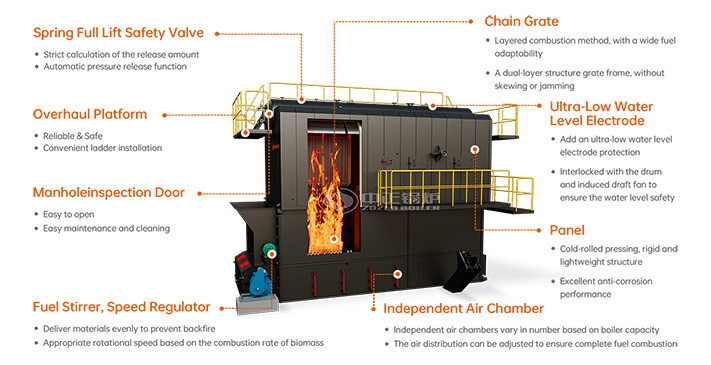

The SZL series biomass-fired boiler is a chain grate water tube boiler designed by ZOZEN Boiler based on advanced international technology and experience. It features a horizontal double-drum and vertical layout structure. The boiler consists of two major parts: the upper part is the heating surface and the lower part is the combustion equipment. The front of the boiler body is surrounded by water-cooled walls. The upper part is connected with drum and the lower part is connected with the header to form the combustion chamber, absorbing the radiation heat of the furnace. At the rear end, a convection tube bundle is arranged between the upper and lower drums. After the fuel is burned in the furnace, the high-temperature flue gas is swept across the convection tube bundle for the secondary return, then guided to a separately arranged economizer and finally enters the dust collector before being discharged through the chimney.

Boiler Advantages

Working Principal

Boiler Specification

| Model | Steam Capacity | Steam Pressure | Steam Temperature | Shipping Dimension | Heat Efficiency |

| SZL6-1.25-SCⅢ | 6 t/h | 1.25 Mpa | 194 ºC | 6.20×2.80×3.65 7.20×2.60×2.80(m) | >83% |

| SZL6-1.6-SCⅢ | 6 t/h | 1.6 Mpa | 204 ºC | 6.20×2.80×3.65 7.20×2.60×2.80(m) | >83% |

| SZL6-2.5-SCⅢ | 6 t/h | 2.5 Mpa | 225 ºC | 6.20×2.80×3.65 7.20×2.60×2.80(m) | >83% |

| SZL8-1.25-SCⅢ | 8 t/h | 1.25 Mpa | 194 ºC | 7.10×3.52×3.65 7.80×3.10×2.80(m) | >83% |

| SZL8-1.6-SCⅢ | 8 t/h | 1.6 Mpa | 204 ºC | 7.10×3.52×3.65 7.80×3.10×2.80(m) | >83% |

| SZL8-2.5-SCⅢ | 8 t/h | 2.5 Mpa | 225 ºC | 7.10×3.52×3.65 7.80×3.10×2.80(m) | >83% |

| SZL10-1.25-SCⅢ | 10 t/h | 1.25 Mpa | 194 ºC | 7.90×3.52×3.65 8.40×3.10×2.80(m) | >83% |

| SZL10-1.6-SCⅢ | 10 t/h | 1.6 Mpa | 204 ºC | 7.90×3.52×3.65 8.40×3.10×2.80(m) | >83% |

| SZL10-2.5-SCⅢ | 10 t/h | 2.5 Mpa | 225 ºC | 7.90×3.52×3.65 8.40×3.10×2.80(m) | >83% |

| SZL12-1.25-SCⅢ | 12 t/h | 1.25 Mpa | 194 ºC | 8.80×3.52×3.65 8.40×3.10×2.80(m) | >86% |

| SZL12-1.6-SCⅢ | 12 t/h | 1.6 Mpa | 204 ºC | 8.80×3.52×3.65 8.40×3.10×2.80(m) | >86% |

| SZL12-2.5-SCⅢ | 12 t/h | 2.5 Mpa | 225 ºC | 8.80×3.52×3.65 8.40×3.10×2.80(m) | >86% |

| SZL15-1.25-SCⅢ | 15 t/h | 1.25 Mpa | 194 ºC | 9.60×3.20×3.65 8.30×3.30×3.00(m) | >86% |

| SZL15-1.6-SCⅢ | 15 t/h | 1.6 Mpa | 204 ºC | 9.60×3.20×3.65 8.30×3.30×3.00(m) | >86% |

| SZL15-2.5-SCⅢ | 15 t/h | 2.5 Mpa | 225 ºC | 9.60×3.20×3.65 8.30×3.30×3.00(m) | >86% |

| SZL20-1.25-SCⅢ | 20 t/h | 1.25 Mpa | 194 ºC | 10.65×3.28×3.60 9.30×3.81×2.80(m) | >86% |

| SZL20-1.6-SCⅢ | 20 t/h | 1.6 Mpa | 204 ºC | 10.65×3.28×3.60 9.30×3.81×2.80(m) | >86% |

| SZL20-2.5-SCⅢ | 20 t/h | 2.5 Mpa | 225 ºC | 10.65×3.28×3.60 9.30×3.81×2.80(m) | >86% |

| SZL25-1.25-SCⅢ | 25 t/h | 1.25 Mpa | 194 ºC | 11.65×3.80×3.60 9.30×3.81×3.00(m) | >86% |

| SZL25-1.6-SCⅢ | 25 t/h | 1.6 Mpa | 204 ºC | 11.65×3.80×3.60 9.30×3.81×3.00(m) | >86% |

| SZL25-2.5-SCⅢ | 25 t/h | 2.5 Mpa | 225 ºC | 11.65×3.80×3.60 9.30×3.81×3.00(m) | >86% |

| SZL30-1.25-SCⅢ | 30 t/h | 1.25 Mpa | 194 ºC | 10.00×3.36×3.60(m) | >86% |

| SZL30-1.6-SCⅢ | 30 t/h | 1.6 Mpa | 204 ºC | 10.00×3.36×3.60(m) | >86% |

| SZL30-2.5-SCⅢ | 30 t/h | 2.5 Mpa | 225 ºC | 10.00×3.36×3.60(m) | >86% |

| SZL35-1.25-SCⅢ | 35 t/h | 1.25 Mpa | 194 ºC | 10.00×3.65×3.85(m) | >86% |

| SZL35-1.6-SCⅢ | 35 t/h | 1.6 Mpa | 204 ºC | 10.00×3.65×3.85(m) | >86% |

| SZL35-2.5-SCⅢ | 35 t/h | 2.5 Mpa | 225 ºC | 10.00×3.65×3.85(m) | >86% |

Workshop

Oversea market

I want to comment