sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

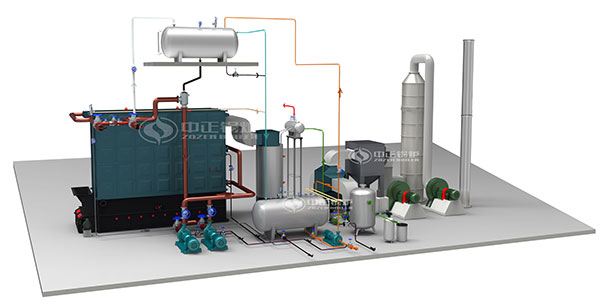

Set up the air preheater. One of the most effective measures to improve the thermal efficiency of thermal oil heater is to use an air preheater for heat recovery. However, the biggest problem of using an air preheater is that low-temperature corrosion of materials easily occurs when sulfur-containing fuels are used. In order to control this kind of corrosion to a certain extent, a minimum limit should be set for metal temperature in the low-temperature zone according to the amount of sulfur in the fuel. Therefore, there should also be a restriction on the temperature of flue gas at the outlet of air preheater. In this way, the highest possible thermal efficiency can be confirmed.

2. Use waste heat boiler for heat recovery. The waste heat boiler uses the waste heat in the flue gas exhausted from the thermal oil heater to heat water or generate steam. The installation of waste heat boiler will not change the fuel consumption of the thermal oil heater itself. The hot water or steam generated by the waste heat boiler can be used for production and heating, which can indirectly save fuel. The installation of waste heat boiler has the following effects: one is improving boiler’s thermal efficiency due to the heat recovery by water usage; the other is reducing the construction costs of unit heat recovery via collecting the flue gas of several thermal oil heaters for heat recovery.

I want to comment